GlassPoint's indoor solar collectors increase efficiency

GlassPoint has leveraged its unique approach to solar thermal energy for oil and gas applications that have proved so successful the company is now building one of the world's largest solar projects in Oman by Pete von Behrens, GlassPoint Chief Technology Officer.

Solar Electricity is growing rapidly, but it can't address all energy segments. Worldwide, industry is the largest user of energy"”larger than transportation, larger than residential"”and two-thirds of industrial energy use is in the form of heat, not electricity. Despite this massive market potential, historically, the global solar industrial heat market has developed slowly. It's made up of vast, but small-scale, niche applications.

At GlassPoint, we discovered one of the biggest and fastest growing industrial markets for solar energy was right in front of us: the oil and gas industry. The traditional energy industry consumes an amount of energy equal to 10 percent of its own production. We set out to design a solar technology specifically to meet this energy demand and are now deploying our solar thermal solution at an unprecedented pace. From the beginning, we knew that cost would be the key to winning over oil and gas producers. When we designed our system, we prioritized cost efficiency, a metric that encapsulates many design and manufacturing choices; everything from optical precision to thermal efficiency to materials costs for steel and concrete.

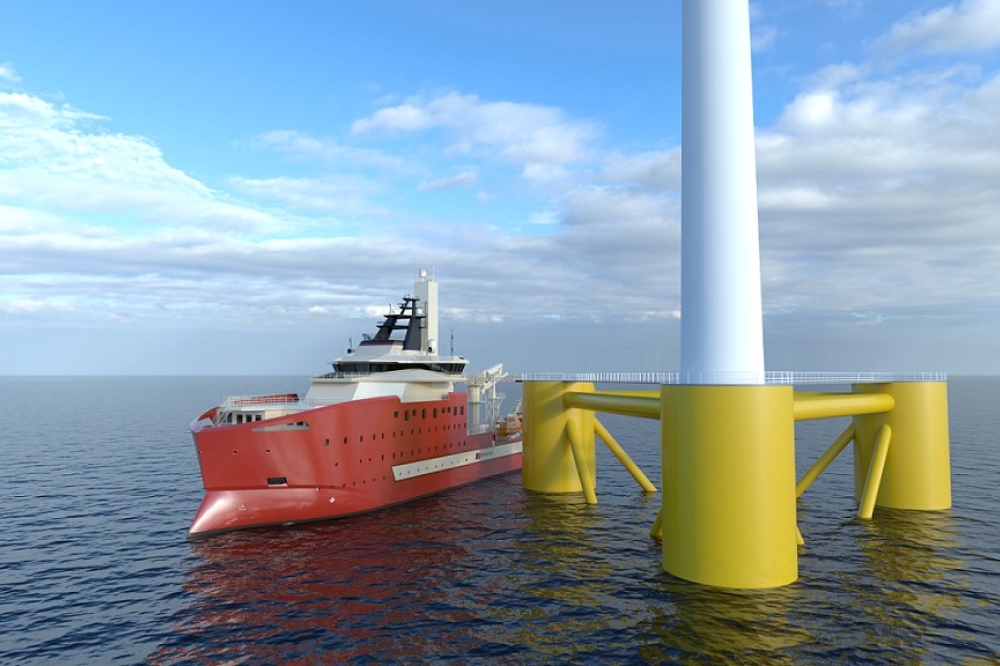

By placing its parabolic mirrors inside commercial greenhouses,

GlassPoint has substantially reduced weight and support infrastructure,

cutting costs in half compared to traditional parabolic trough designs.

In contrast, most other solar thermal systems differentiate themselves by maximizing optical efficiency. This is because they are made up of similar materials (glass mirrors, steel supports, large drive motors) and when the materials of construction are similar, higher optical efficiency can mean higher cost efficiency.

As a result, there have been decades of focus on optical efficiency. The concentrating solar thermal industry has invested hundreds of millions of dollars in improving optical efficiency by a few percentage points. These advances are important and have been critical to the development of the industry, but the incremental advances in optical efficiency simply aren't enough to keep driving costs down. This diminishing rate of optical efficiency improvements led us to shift our focus to other approaches to cutting costs. We combined the age-old design of the agricultural greenhouse with today's gas-fired oilfield boilers to create a radically new kind of solar field.

The result is our "enclosed trough" technology, which moves the solar collectors from the dusty, windy outdoors into a clean, zero-wind greenhouse. That one change enabled us to use lighter materials that are significantly lower-cost. Ultra-thin aluminum sheet mirrors have replaced heavy glass, resulting in 90 percent reductions in collector weight. Total weight of the system including the greenhouse, is half that of older technologies.

The resulting system sacrifices some optical efficiency, but it delivers far higher cost efficiency, due to the huge savings in materials costs, maintenance and resulting operational advantages. Our innovations make solar steam generation newly viable for one of the world's biggest industries, creating opportunities to significantly reduce greenhouse gas emissions along the way. We are now constructing what will become one of the world's largest solar plants of any kind on an oilfield in south Oman. Once complete, the gigawatt-scale Miraah plant will produce over 6,000 metric tons of emissions-free steam a day, an alternative to steam generated from natural gas, which is used to produce heavy or viscous oil. A 2017 report from the International Energy Agency (IEA) noted that Miraah alone will be bigger than all other industrial solar heat installations combined.

GlassPoint was also recently selected by Aera Energy, a joint venture with ExxonMobil and Shell, to build California's largest solar plant on the Belridge oilfield, one of the United States' largest and oldest oilfields. The Belridge Solar project will include an 850 MWt (megawatts thermal) solar thermal facility generating steam and a 26.5 MWe (megawatts electric) photovoltaic system generating electricity to power other oilfield operations. This scale allows us to achieve volume efficiencies and reduce costs that wouldn't be feasible in smaller installations.

Wind is the main cost driver for solar energy. In Oman, home to our Miraah project, more than 70 percent of the available sunlight is captured at wind speeds above 6 m/s, or 13 miles per hour. In these conditions, the buffeting action of the wind will reduce the performance of exposed parabolic troughs and towers. This is because each individual mirror acts like a giant sail in the wind, bending and flexing as the wind blows. Even tiny movements reduce concentration on the receiver, resulting in energy loses. For example, at wind speeds of 8 m/s the Eurotrough design, an exposed parabolic system, experiences losses of 15 percent.

In these traditional outdoor systems, every mirror must be reinforced against the wind, and each one must be extremely precise and extremely robust. To achieve this dual-function, lots of steel and expensive foundations are used to armor and anchor the mirrors into the ground. By bringing the entire system inside a greenhouse, we eliminated the wind load on mirrors altogether. In our system, only the outside wall of the greenhouse needs to be reinforced against the wind. The greenhouse serves as protection, structure and foundation in one, while the sole function of the solar collectors indoors is to turn sunlight into energy. Our mirrors are lightweight, installed by hand, and hung by small wires that are thinner than a pencil. Compared to the traditional Eurotrough design that weighs 25 kg/m2, GlassPoint's solar collectors weigh less than 5 kg/m2.

The weight of these materials adds up and has a huge impact on a system's cost efficiency since the heavier the materials, the more expensive it is to transport and install them. GlassPoint reduced the amount of materials used throughout the entire system, cutting the cost of our system in half compared to traditional parabolic troughs.

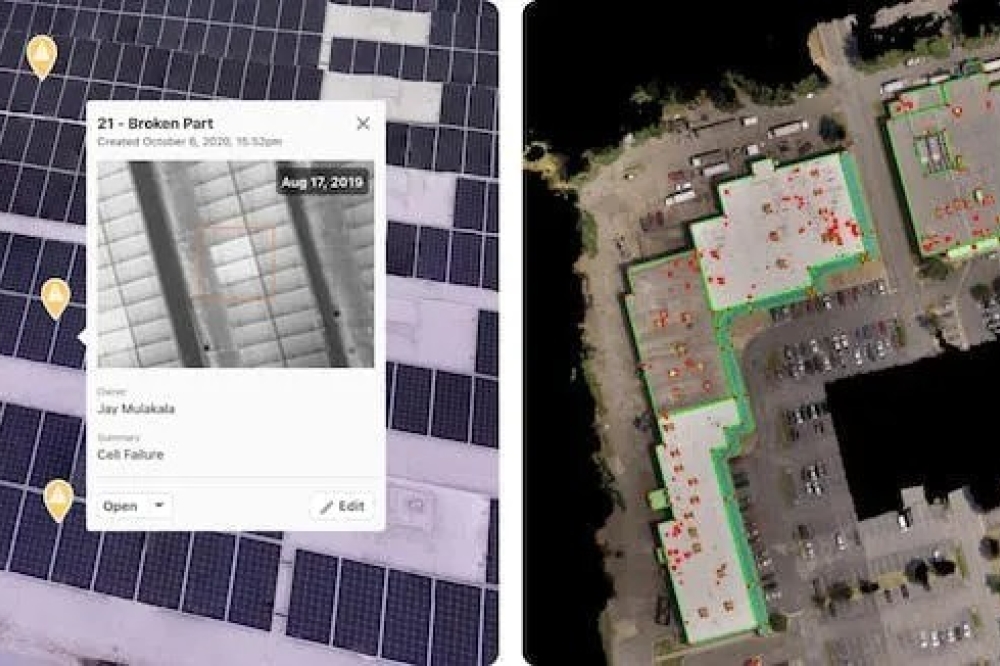

Soiling, the accumulation of small particles like sand or dirt, is another major pain point for solar in harsh climates, like dusty oilfields or desert regions throughout the Middle East and North Africa. Areas surrounded with sand and high ambient dust are often places of high humidity. When the solar collectors are exposed, the particles will stick to the mirror surfaces, scattering sunlight and reducing system output.

On a typical day in south Oman, soiling rates cause approximately 2-3 percent reduction in performance per day. That means a solar project may lose 2 percent of its energy every day that it goes unwashed. Typical outdoor systems are washed about once a week, often manually or with spray trucks. A week without washing adds up to a 15 percent performance drop.

Dust storms, which may happen a handful of times a year or more, can knock performance 20 percent in a single day. In GlassPoint's enclosed trough design, the mirrors are protected by the greenhouse. An automatic washing system is used to clean the roof of the greenhouse, removing dust and debris every night. By the time the sun comes up the next day, performance has been fully restored and the system is ready to go.

Developing a new kind of solar"¦ to operate indoors

The greenhouse enclosure eliminates the wind load and prevents soiling, dramatically reducing capital and operating costs compared to outdoor systems. Of course, the greenhouse adds cost, but not as much as one might think. In fact, the most novel thing about GlassPoint's innovation is actually not that novel.

The Miraah solar field will span an area of 2 km2 once complete.

The greenhouse industry has been perfecting and cost optimizing this technology for the past century. Greenhouses are designed to maximize the transmission of sunlight and withstand extreme weather events. Our optical efficiency is lower than outdoor systems due to the extra layer of glass transmission through the roof and shading caused by the structure. However, these loses, which total around 20 percent, are made up for in three ways:

1) decreased capital costs by using less materials 2) reduced performance losses from soiling and wind deformation and 3) reduced operating expenses due to automated washing. The plant's lifetime is also extended by shielding the components from the harsh outdoor environment.

Our focus on cost efficiency drove us to innovate beyond all notions of solar thermal and develop an entirely new kind of solar"”one that operates indoors. Anything that's been developed to work outside on traditional systems, won't work for GlassPoint's enclosed trough. That means we're still early in our innovation journey, and continue to explore ways to simplify the design, reduce overall materials and achieve further savings in our next generation designs. These innovations coupled with the scale of the oil and gas industry have allowed us to achieve unmatched cost efficiency, which is paving the way to future applications, some on the oilfield and beyond.