k-Space Receives Readers’ Choice Award from USGlass Magazine

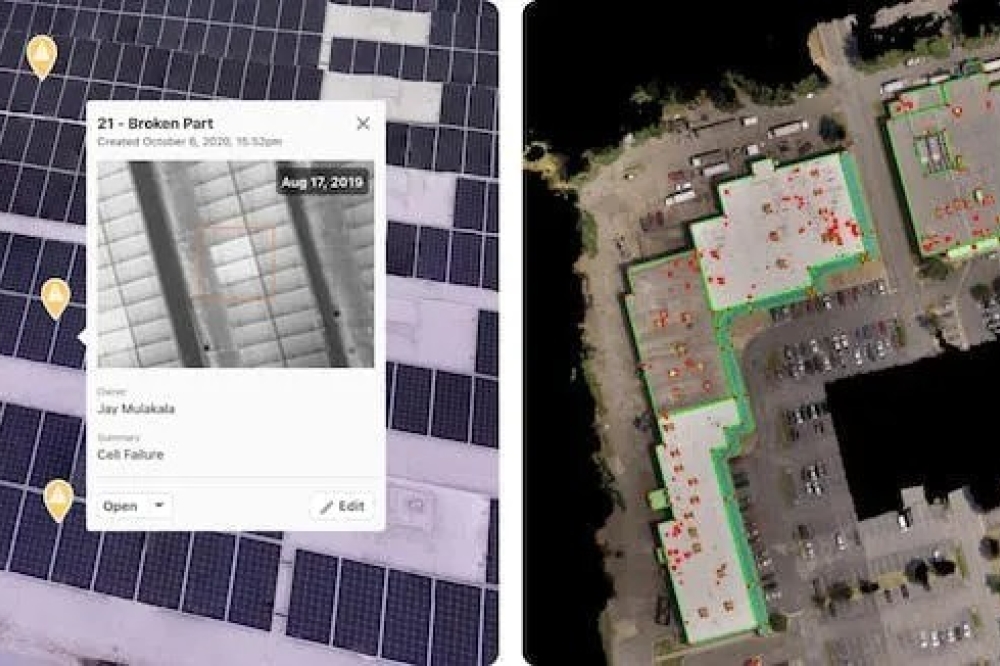

The k-Space Glass Breakage and Defect Detection system is designed to reduce scrappage costs while speeding manufacturing processes

k-Space Associates of Dexter, Michigan (USA) has been

recognized with a Readers’ Choice Award by USGlass Magazine for its Glass

Breakage and Defect Detection solution. This innovative system detects

microscopic chips, cracks, and defects in glass panels, as well as

sub-millimeter changes in panel thickness, providing real-time alerts to

manufacturing operators about potential problems.

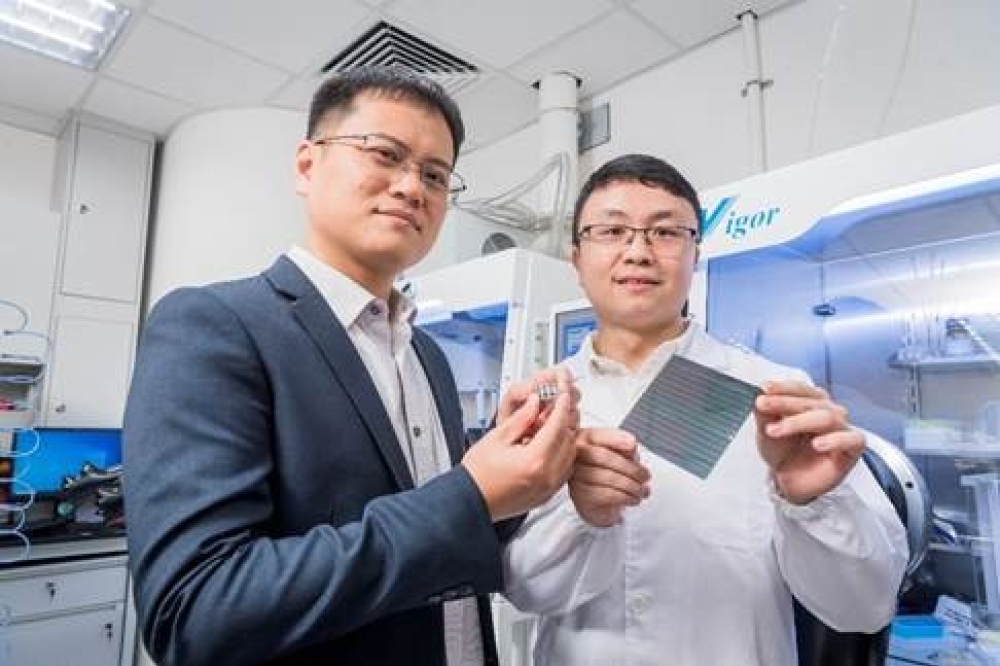

The technology’s ability to identify and address anomalies

during the production process makes it particularly relevant to solar cell

manufacturing, where thin glass panels are essential for efficiency and

performance. Defects or thickness inconsistencies in glass substrates can

compromise the durability and efficiency of solar cells, making precise

inspection tools critical to ensuring product quality.

k-Space’s glass inspection solutions are integrated

seamlessly into existing manufacturing infrastructures, working in tandem with

factory alarms, PLC alerts, and other systems. They also provide real-time

analysis of key parameters like color calibration, film and coating thickness,

and panel edge quality. The system enables immediate scrapping of defective

products and identification of upstream manufacturing issues, helping to reduce

downtime, scrap costs, and product returns.

“We are especially pleased to receive this award from

USGlass Magazine because it’s chosen by glass industry professionals,” said

Darryl Barlett, CEO of k-Space. “Our glass inspection tools are helping

companies build better products, reduce returns, and protect their margins.”

For more information, visit www.k-space.com.