Thin and flexible organic PV devices engineered to resist stress

A flexible polymer-based solar cell that can be heated up to 120 degrees Celsius without reducing its ability to harvest energy has been developed by a team led by RIKEN researchers (PNAS, "Thermally stable, highly efficient, ultraflexible organic photovoltaics"). The combination of flexibility and thermal robustness makes it attractive for powering wearable sensors and devices.

Organic solar cells use conductive, carbon-based polymers instead of rigid silicon to capture sunlight and convert it into electricity. They can thus be attached to irregular backings such as clothing without breaking.

Previously, Kenjiro Fukuda of the RIKEN Center for Emergent Matter Science and his team had encapsulated organic solar cells in other polymers to improve their compatibility with textiles by making them tougher and more water resistant.

However, one problem that still limits the long-term lifetime of flexible solar cells is their poor resistance to temperature changes. Thermal stress can make polymers brittle or cause them to become less conductive through expansion.

Fukuda, with group leader Takao Someya and colleagues from Japan and the United States, overcame this problem and fabricated organic solar cells with enhanced thermal stability by modifying the device's active layer"”a complex, light-absorbing polymer composed of fluorine atoms and sulfur-containing aromatic rings. Adding linear hydrocarbon chains to this molecule triggered the aromatic rings to stack in a "˜face-on' orientation that boosted the polymer's crystal strength.

The team replaced the conventional plastic substrates used to support the active layer with transparent polyimides that are mechanically stable over a wide temperature range. To form the polyimide film on a supporting plate, they used a wet-chemistry process, rather than vacuum deposition, since it is more amenable for fabricating large-area films.

But a wet-chemistry process necessitates carefully controlling the substrate's surface energy: if the substrate is too hydrophobic, the polyimide precursor solution will bead and not form a film, whereas if it is too hydrophilic, the polyimide film will adhere too strongly, making it hard to peel off. The researchers achieved the right surface energy by adjusting the thickness of a hydrophobic layer and treating it with oxygen plasma.

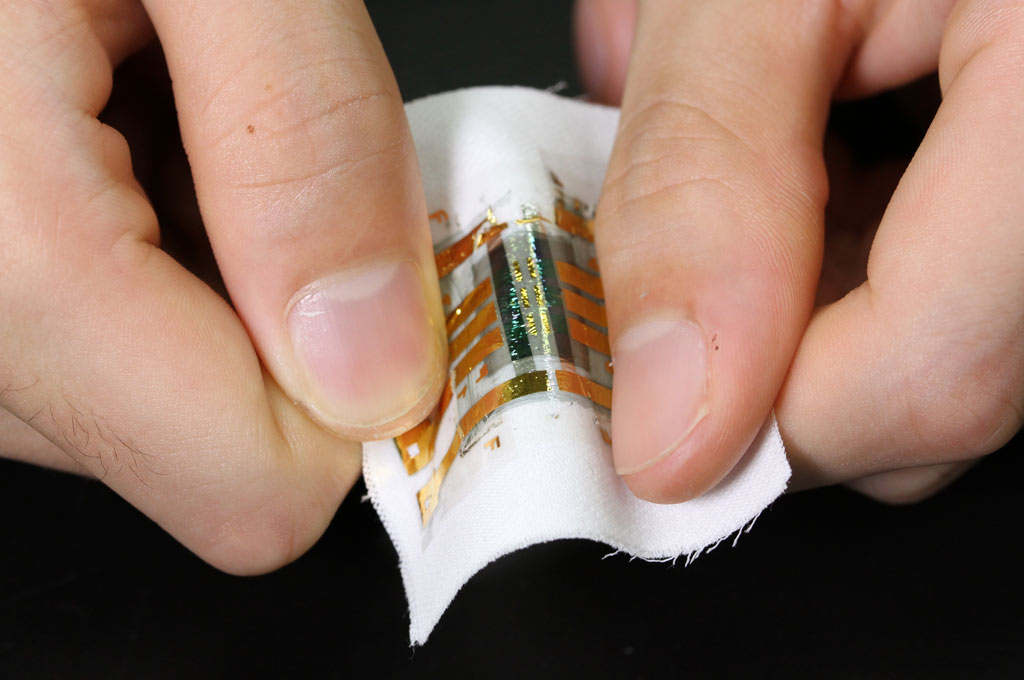

Following a final encapsulation step, they tested the behavior of their solar cell as it was rolled, folded, and crumpled repeatedly at different temperatures. The power conversion efficiencies remained at near-record rates despite the mechanical and thermal stress. This inspired the group to attach the devices to fabrics using "˜hot-melt' technology developed for the apparel industry (Fig.).

"The hot-melt process gives almost perfect adhesion of our ultrathin organic solar cells onto textiles, with no degradation in performance," says Fukuda. "We're now discussing these results with our collaborators to find a good strategy for commercialization."