Researchers develop cheaper manufacturing process for TCO films

Researchers at Empa have succeeded in developing a method of producing such TCO films, as they are known, that is not only cheaper, but also simpler and more environmentally friendly.

It is a requirement of the touchscreens for all our everyday gadgets that they are transparent and at the same time electrically conductive. Solar cells are also unable to operate without such a film, which allows sunlight to pass through it, but can also conduct the current generated. Conventional "transparent conductive oxide" (TCO) films consist of a mixture of indium and tin oxide. Indium in very much in demand in the electronics industry, but is rare, and therefore expensive.

A cheaper option (at least in terms of the materials used) employs zinc oxide mixed with aluminium, which is usually applied to the substrate in a high vacuum by means of plasma sputtering. However, the manufacturing process is complex, making it similarly expensive. In addition, it is energy-intensive and therefore not ideal from an ecological perspective. Empa researchers at the Laboratory for Thin Films and Photovoltaics have now developed a water-based method of applying a TCO film made of aluminium and zinc salts onto a substrate "“ without a vacuum.

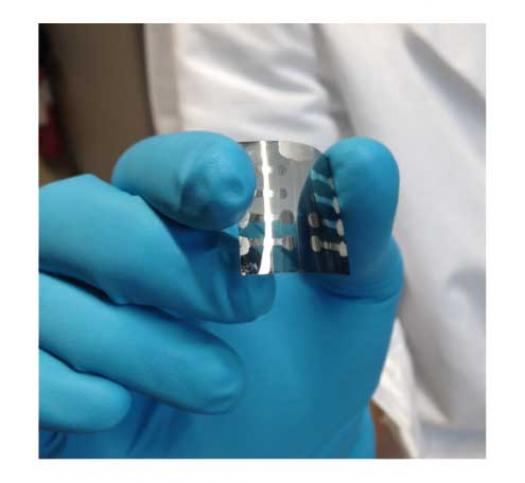

Another advantage of the new method is that during the last stage of production, in which the TCO film is "cured", the substrate does not have to be heated to 400 to 600 degrees as was previously the case, but only to 90 degrees. "This means that our method is not only cheaper and more environmentally friendly, but also requires less energy and it is even possible to use more heat-sensitive substrates, such as flexible plastics", explains Harald Hagendorfer from the research team.

The transparent conductive film under an electron microscope: the crystals are grown widthways, close together using a "molecular lid" - giving the film optimum conductivity.

The biggest difference, however, lies in the principle behind the manufacturing process. Whereas with the sputtering method, the TCO film is deposited onto the substrate in a high vacuum using a high-energy plasma, with the Empa method, this occurs through a type of molecular self-organisation. Thus, the TCO film grows "by itself" - with no subsequent high-temperature thermal treatment. A short irradiation process with a UV lamp is sufficient to produce excellent conductivity.

Yet here too, a problem had to be overcome: aluminium zinc oxide (AZO) prefers to grow tapering upwards - like stalagmites in a limestone cave. For optimum conductivity, however, there must be no gaps between the "pillars". The simple solution devised by the Empa team was to use a "molecular lid" during the crystal growing process. Thus, the material can only grow to a limited height and instead grows widthways, resulting in a compact film which is transparent and has optimum conductivity.

The Empa team, led by Ayodhya Tiwari, is now working to further improve the AZO films. In terms of electrical conductivity and transparency, they can already compete with indium-containing TCO films, but some optimisation is still required with regard to their use in solar cells. Tiwari and his colleagues want to reduce the TCO film thickness from one to two microns to just a few hundred nanometres. This would allow the AZO films to be used in flexible solar cells, further reducing the amount of material used. Tiwari's team is also currently working with another Empa research group on the indium-free production of organic solar cells, which would make the process cheaper and more sustainable. There certainly seems to be a considerable amount of interest in the new method. Industrial project partners are already on board, opening up the possibility that Empa TCO films may soon be manufactured on a large scale.

Journal Reference:

H. Hagendorfer, K. Lienau, S. Nishiwaki, C.M. Fella, L. Kranz, A.R. Uhl, D. Jaeger, L. Luo, C. Gretener, S. Buecheler, Y.E. Romanyuk, A.N. Tiwari. Highly Transparent and Conductive ZnO: AI Thin Films from a Low Temperature Aqueous Solution Approach. Advanced Materials, 2014 DOI: 10.1002-adma.201303186