Cooking up efficient perovskite solar cells

Additive DMSO favours crystal growth ... but only up to a certain point, says Helmholtz-Zentrum Berlin team

Solar cells made of crystalline silicon still account for the lion's share of roof installations and solar farms. But other technologies have long since become established such as those that convert sunlight into electrical energy through use of extremely thin layers of solar-cell material deposited upon a substrate.

The perovskite solar cells that Eva Unger and her team at the Helmholtz-Zentrum Berlin (HZB) are researching have efficiencies approaching those for cells made of crystalline silicon. But industrial-scale fabrication is still a long way off.

But now her team is taking the next step and developing scalable methods for coating larger surfaces.

At the Hybrid Silicon Perovskite Research, Integration & Novel Technologies (HySPRINT) Innovation Lab, an infrastructure for collaboration between HZB and industry, the team is concentrating on processes that have already proven their importance in industry to start with.

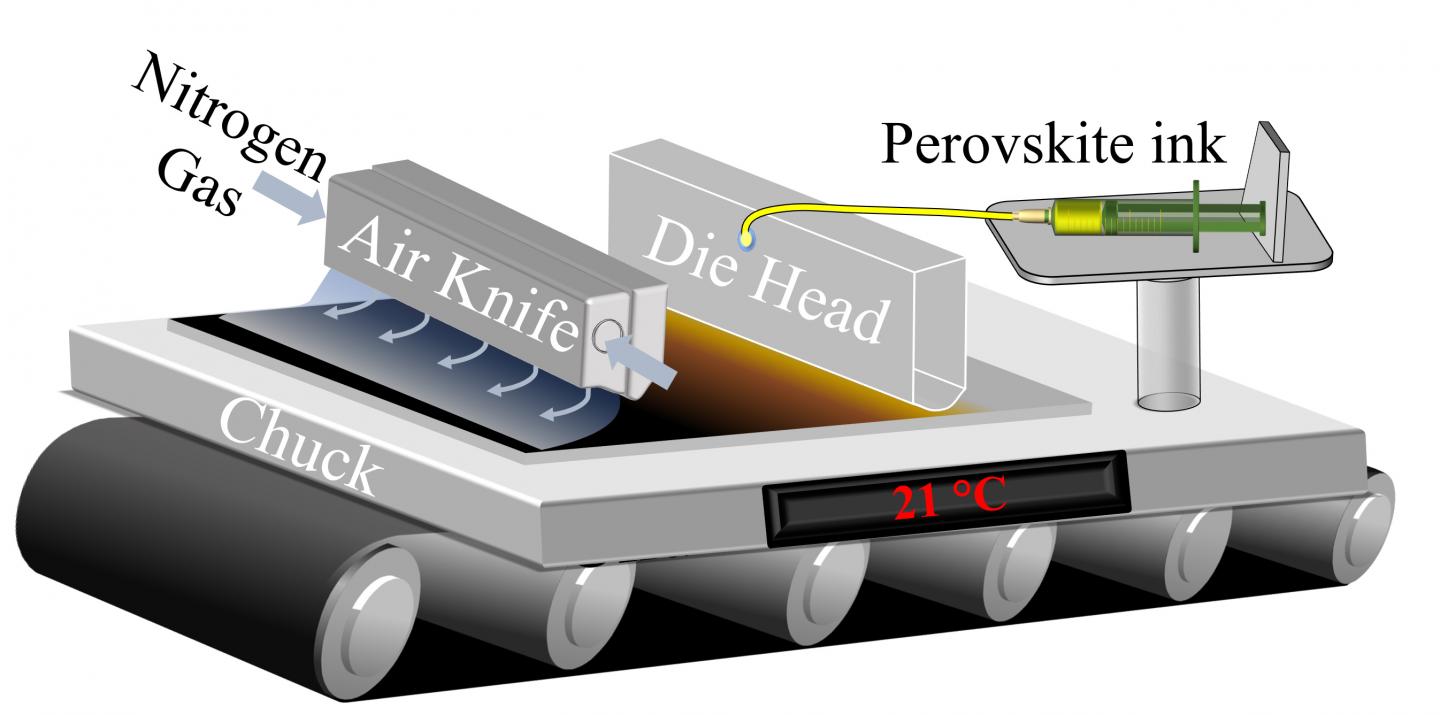

"We have experimented here with slot-die coating", she explains. In this process, the 'ink', as the thin liquid solution of perovskite precursor, solvent, and additive is known in the trade, flows from a slit-shaped nozzle and falls like a curtain onto the glass substrate being conveyed below that will later become a solar cell. After application, crystallisation begins and an ultra-thin layer of a semiconducting perovskite structure grows.

Unger, together with her team members doctoral student Jinzhao Li and Janardan Dagar, have now discovered that the exact amount of the organic solvent dimethyl sulphoxide (DMSO) in the material ink is critical for this process.

(The picture above shows the liquid solution of perovskite precursor, solvent, and additive flows from a slit-shaped nozzle onto the glass substrate being conveyed below.)

Unger uses it as an additive because it has an remarkable effect on the ink. "DMSO induces crystallisation nuclei for the perovskite", says the researcher. Crystallisation nuclei usually are tiny grains that help jump-start a crystal and promote its growth. "During X-ray diffraction experiments at BESSY II, we saw quite a big difference between inks with and without DMSO added", the physical chemist explains.

However, as her team has found out in many experiments, the amount added plays a decisive role here. More DMSO favours crystal growth - up to a certain point. If this is exceeded, other processes come into play and the resulting microstructure reduces the performance of the solar cells.

"It's like seasoning a soup", says Unger. "If you add too little, it remains bland. If you add too much, it won't taste good either. So you need to add just the right amount to make it best." In addition to the optimal composition, the HZB team has also thoroughly investigated the ageing processes and thus the storage life of the inks. "This is an aspect that has received little attention so far", Unger explains. "The age of a perovskite precursor ink can influence device performance. This is an important factor that must be considered when developing inks and processes."

'20.8 percent Slot‐Die Coated MAPbI3 Perovskite Solar Cells by Optimal DMSO‐Content and Age of 2‐ME Based Precursor Inks' by Jinzhao Li et al; Advanced Energy Materials 25 January 2021