Optimising the manufacturing process of PERC cells

SCHMID Group claims it can optimise the manufacturing process of PERC cells, thereby reducing the consumption of chemicals

A large part of the red light (long wave) penetrates conventional solar cells without power generation. Since the introduction of PERC technology this light is exploited as well: A dielectric layer on the back of the cell reflects the light which penetrates through to the rear side without generation of charge carriers. The photons thus obtain a "second chance" to generate electricity. Consequently the efficiency of the solar cell increases.

The smoothest possible back surface should be used to minimize recombination on the back of the solar cell. The surface on the front, however, should still be textured. The problem: Since both sides are textured in a batch process, the texture on the back must be removed again in a separate step. This always devours large quantities of chemistry.

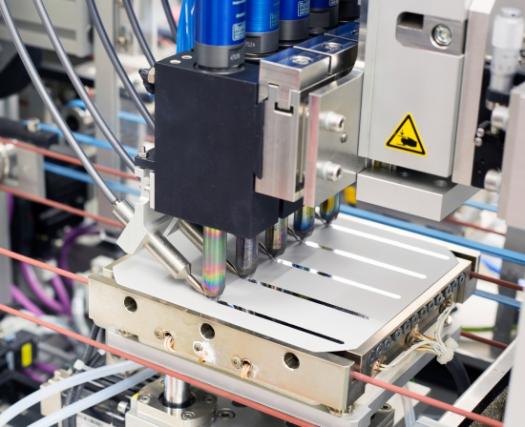

Schmid proppse a solution with the SCHMID Inline System for alkaline texture. The wafers are irrigated with potassium hydroxide and additives from above and thus are textured; at the same time the process ensures a smoother back, which SCHMID will polish later in high quality.

Keyword polishing: instead of hydrofluoric and nitric acids that are difficult to handle SCHMID now uses an alkaline solution. The effect: lower process costs, since no polluting nitrogen oxide is produced any more which is expensive to dispose.

When using tin instead of silver for the back busbars, you turn another set screw to reduce costs and in particular to improve the results of the PERC process, since the typical reason for recombination, the silver back busbar, is avoided. The SCHMID TinPad can apply tin busbars both during cell production after metallization or in module production before stringing.

With the PERC technology the cell performance can be increased to more than 21 percent - especially when a selective emitter is used. In this combined printing and etching process the high phosphorous doping on the cell is selectively etched and maintained only there where contacts are printed subsequently. This reduces the recombination. Current production results by customers of the equipment manufacturer SCHMID show an increase in efficiency by 0.3 - 0.4 percent.

To change the production line to selective emitter technology only two machines need to be integrated: An inkjet printer, which applies the wax mask, and a wet process machine for etching back the emitter and for stripping the wax mask. Through the automation with Bernoulli grippers the SCHMID inkjet printer reaches a throughput of up to 3,300 wafers per hour. The wax solidifies directly. Thus time-consuming (and expensive) finishing treatments are no longer necessary. In addition, the wax can be stripped very easily after the etching process.

It cannot be predicted yet which cell concept will prevail in the medium term. But those who decide in favor of a SCHMID production line for the production of monocrystalline PERC-cells today can produce bifacial cells with the same cell production line tomorrow. With the Multi Busbar Connector for module production the SCHMID portfolio includes a technically mature system which uses round copper wires instead of flat bands to join solar cells to strings. The improved light yield and the lower series resistance promise an increase in power of 5 W per standard module.