Energy improvement through innovation

As demand for renewable energy grows, photovoltaic (PV) modules, or panels, are being deployed in various types of solar PV installations. However, the most popular use of these modules is in grid-connected applications, where the output of the solar PV system must be 50 or 60 Hz AC power that can be fed into the main power grid. Such systems provide end users with clean energy to power their appliances during daylight hours, while also allowing them to sell any excess energy they generate back to the power utility. Equally important, is the fact that users can still receive power from the grid, when solar power is unavailable during overcast conditions or at night.

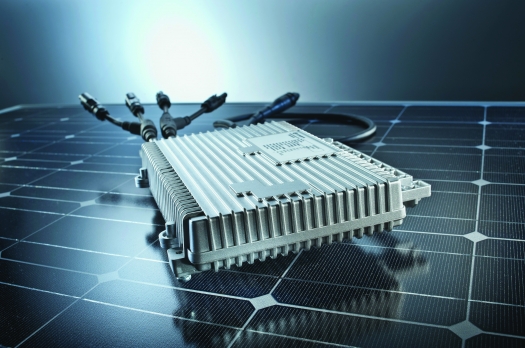

Nevertheless, grid-connect solar PV systems impose certain requirements. For example, PV modules produce DC power at peak levels up to 250 W. So in most installations, multiple panels will need to be connected in series to generate sufficient power levels for the home or business being powered. The output of those multiple panels will then need to be converted from DC to grid-compatible AC power. That requires additional electronic equipment in the form of a solar power inverter. Those are the most basic needs for grid-connected solar PV systems. The design of these systems is heavily influenced by the end user's requirements for economy and reliability. Because of these demands, the design of solar PV systems is evolving from an architecture that relies on a single power inverter in each system to one that employs multiple micro inverters.

The adoption of the micro inverter based solar PV architecture promises to reduce the cost per watt of the solar PV system over its operating lifetime, while increasing the amount of energy harvested. However, as such systems are relatively new the issue of micro inverter reliability must be addressed.

Traditional Solar PV Architecture

In a conventional, grid-connected solar PV installation, the modules are connected in series, or daisy chained, to form a "string". The output of this string is fed to a central inverter (also referred to as a "string inverter"), which converts the high DC voltage generated by the string into AC that can be fed into the grid.

In this type of solar PV system, installation is complex and expensive. Special skills are required to ensure the system is setup for optimum performance and to ensure that the necessary safety procedures are followed. The safety requirements are dictated by the presence of high and potentially lethal DC voltages and currents in the system. The voltage produced by the string can be as much as 900 V at

5 A. This is sufficient to cause a fatality should someone touch a live connection. At the same time, systems based on DC strings are very sensitive to how the components are selected and configured during installation. Maximum energy harvesting can only be achieved if every module is matched exactly for performance and then installed so that the same level of solar radiation reaches each solar cell in every module. These requirements are difficult to meet under real-world conditions. Consequently, many solar PV systems do not perform up to their potential, often falling well short of their energy-harvesting capability. This lack of performance can be caused by any object that blocks a module's view of the sun. In some cases, shading from tree branches is the problem. But even objects as small as an antenna or vent pipe can dramatically lower the energy produced by a string.

While some obstacles may be accounted for during installation, some cannot. Over time, dust and dirt can build up unevenly on the modules causing some modules or even a few cells within the modules to receive less solar energy than other modules. Unfortunately, because the modules are connected in series, the poorest-performing module will determine the overall performance of the entire system. Just one shadowed module significantly limits the energy generated by the system as a whole and the higher potential energy of the un-shadowed modules is wasted.

Often a system with relatively few obstructed solar cells won't even produce half of its peak power capability. And in those cases where shadowing affects several modules, the system may not generate any power output. Since the weakest modules have such impact on the efficiency of the solar PV system, the individual modules must be pre-selected prior to installation to ensure their uniform performance. Meeting this requirement adds to the cost of manufacturing the modules and to the cost of installing them.

A more complete solution

There is another, more complete solution "“ a micro-inverter based architecture. In this environment, a micro inverter is either built into, or attached to, each PV module. A micro inverter converts the DC produced by each module to AC that can be fed directly to the grid. With this arrangement, each module becomes a standalone solar PV system with its own optimised energy production output.

By replacing the large, central inverter with many smaller micro inverters, the micro inverter architecture eliminates the single point of failure that makes conventional solar PV systems vulnerable. Installation of the systems also becomes safer, easier and faster with micro inverters. Instead of dealing with high-voltage DC circuits that require special wiring, installers work with lower-voltage DC and standard AC line voltages and cabling. Wiring up of the system is greatly simplified since the micro inverters are essentially plug-and-play units. This change can reduce installation time and cost by 15% to 25% versus installation of a conventional solar PV system. The micro inverter architecture is also flexible and scalable. Modules can be positioned on any plane, or on multiple planes within a single system.

For the end customers who purchase solar PV systems, micro inverters offer several benefits. The systems are inherently safer than the conventional solar PV systems, generate more power, and save money in the long run. By optimising the energy harvested from each module, micro inverters can extract 5% to 20% more power from the installation than would be possible with a central inverter. Although the up-front cost of the system can be higher with micro inverters, the added cost of putting a micro inverter at every module can be offset in time by the savings accrued from not having to replace the central string inverter, one or more times. That said, for installations of 2KW or less, a solar architecture using micro inverters is usually around the same cost as one using a central inverter.

Evolving benefits

It's becoming increasingly clear throughout the solar energy industry that conventional DC string architectures have limitations in rooftop PV solar installations for both domestic and commercial premises. The discrepancy between the energy they could potentially harvest and what they actually harvest is significant. This lack of system efficiency in the real world is hampering adoption of solar-electric technology.

Micro inverter based systems will address both energy harvesting performance and cost issues. As a further advancement, we can expect many PV module manufacturers to build micro inverters into their products. The resulting AC modules, which will be solar modules with grid-ready AC output, will become industry-standard products. This standardisation will dramatically reduce the PV system installation time, complexity and cost. Equally important will be the benefits to PV system users, who will harvest more electricity from their systems and see their investments in solar energy paid back over much shorter periods of time.

© 2013 Angel Business Communications.

Permission required.